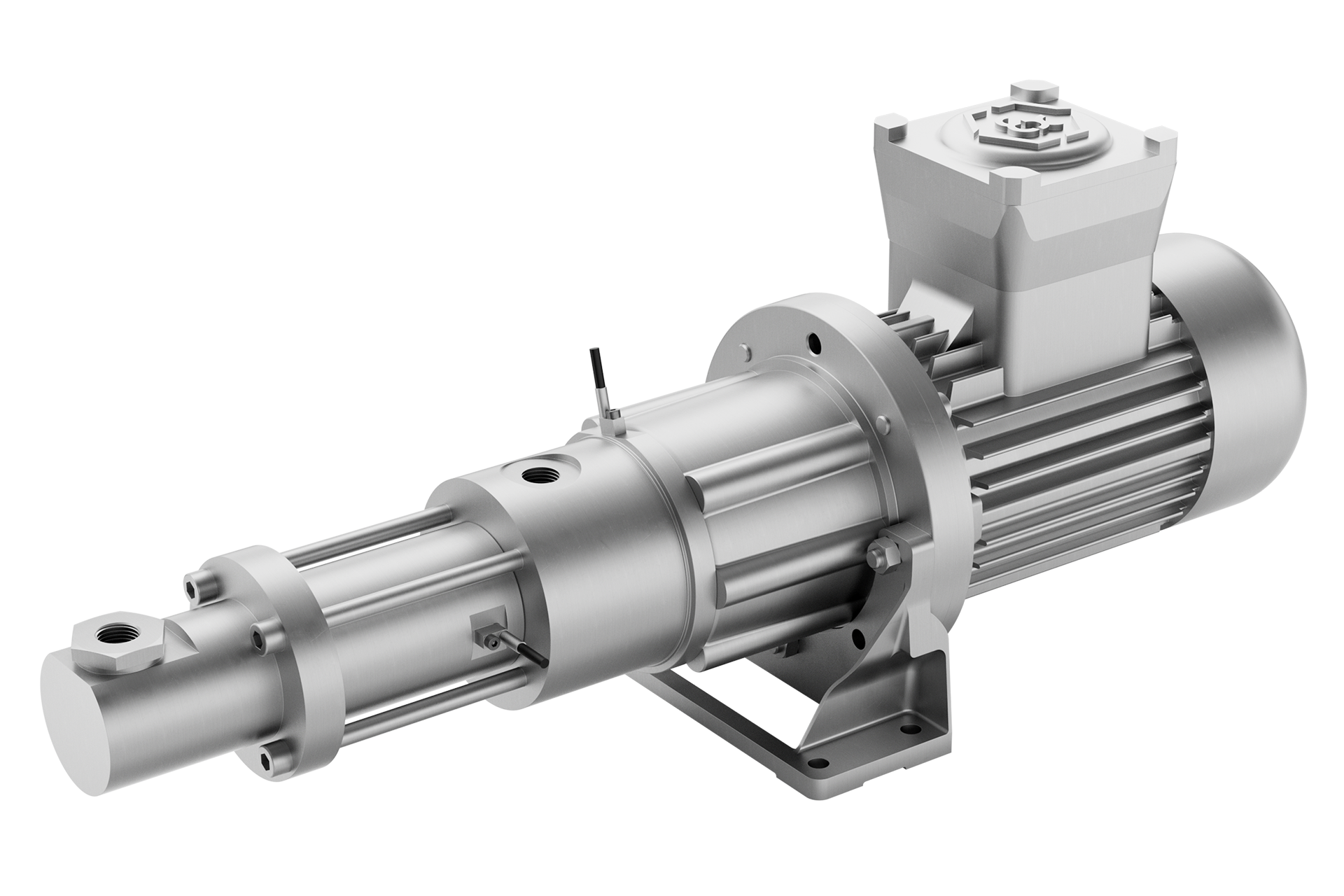

KRAL F Series Screw Pumps.

The screw pump for Future Fuels.

When future meets experience.

In the ever-changing world of energy technologies, future fuels play a key role. They do not only promise a more sustainable alternative to conventional fossil fuels, but also drive innovation and efficiency in various industrial applications. The KRAL Future Fuels pump offers high efficiency for various Future Fuels and a wide range of applications thanks to the use of corrosion-resistant stainless steels.

Operation, materials, components.

- Delivery rate: 5 to 280 l/min.

- Viscosity: 0.2 to 500 mm2/s.

- Rotation speed: up to 4,000 min-1.

- Max. differential pressure: 120 bar.

- Max. temperature: +80 °C.

- ATEX: Zone 1 & 2.

- Future Fuels: Biofuels, Methanol, Ammonia, Ethanol, LFO, HVO, FAME.

KRAL F series at a glance.

All media wetted parts made of stainless steel.

Hermetic sealing with magnetic coupling.

Approved for use in in ATEX Zone 1 & 2.

Differential pressures up to 80 bar (LFO, biofuels) / max. 60 bar for methanol and up to 40 bar for ammonia.

Excellent efficiency degree.

Low pulsation and low shear conveying.

Almost linear conveying characteristics.

Very low noise emissions.

Suitable for fuels with acid value > 0.5 mg KOH/g.

| Technical data | 15-20 | 32-42 | 55-74-85 | 105-118 | |

|---|---|---|---|---|---|

| Delivery rate (2,900 min-1, 40 bar, 1 mm2/s) | l/min | up to 25 | up to 60 | up to 120 | up to 180 |

| Max. differential pressure | bar | 120 | 120 | 120 | 120 |

| Max. temperature | °C | 80 | 80 | 80 | 80 |

| Viscosity | mm²/s | >0,2 | >0,2 | >0,2 | >0,2 |

| Max. rotation speed | min-1 | 4,000 | 4,000 | 4,000 | 4,000 |

| Max. supply pressure | bar | 16 | 16 | 16 | 16 |